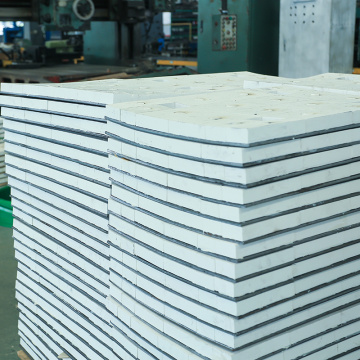

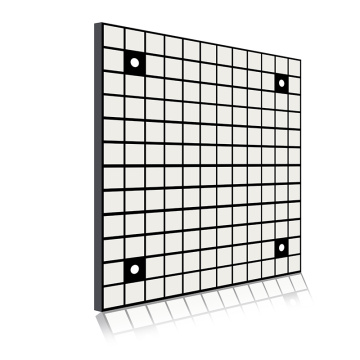

rubber lining plate along the plate bottom

$1-10 /Kilogram

| Payment Type: | L/C,T/T,D/P,D/A,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DEQ,DDP,DDU,Express Delivery,DAF,DES |

| Min. Order: | 10 Kilogram |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Tianjin |