Rubber Liner series

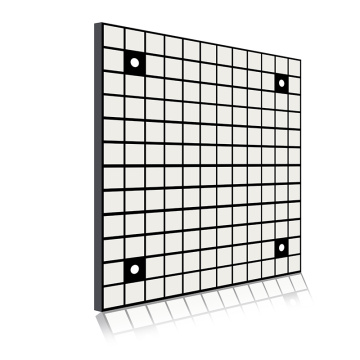

Benefits of using a ceramic rubber composite liner in a cylinder mixer include:

-

Enhanced wear resistance: The ceramic tiles provide exceptional hardness and abrasion resistance, protecting the cylinder mixer from wear caused by the movement of materials during mixing.

-

Impact resistance: The rubber matrix acts as a shock-absorbing layer, reducing the risk of tile breakage or damage due to impacts or high-speed material flow.

-

Noise reduction: The combination of ceramics and rubber helps dampen noise generated during the mixing process, improving the working environment.

-

Corrosion resistance: Ceramic materials are highly resistant to corrosion, making the composite liner suitable for applications involving corrosive materials or environments.

-

Easy maintenance: The ceramic rubber composite liner is typically easy to install and replace, minimizing downtime and maintenance costs.

When selecting a ceramic rubber composite liner for a cylinder mixer, it's essential to consider factors such as the type of materials being mixed, operating conditions (temperature, pressure, etc.), and the specific requirements of the application. Consulting with a manufacturer or supplier specializing in industrial linings can help you choose the most suitable liner for your cylinder mixer.

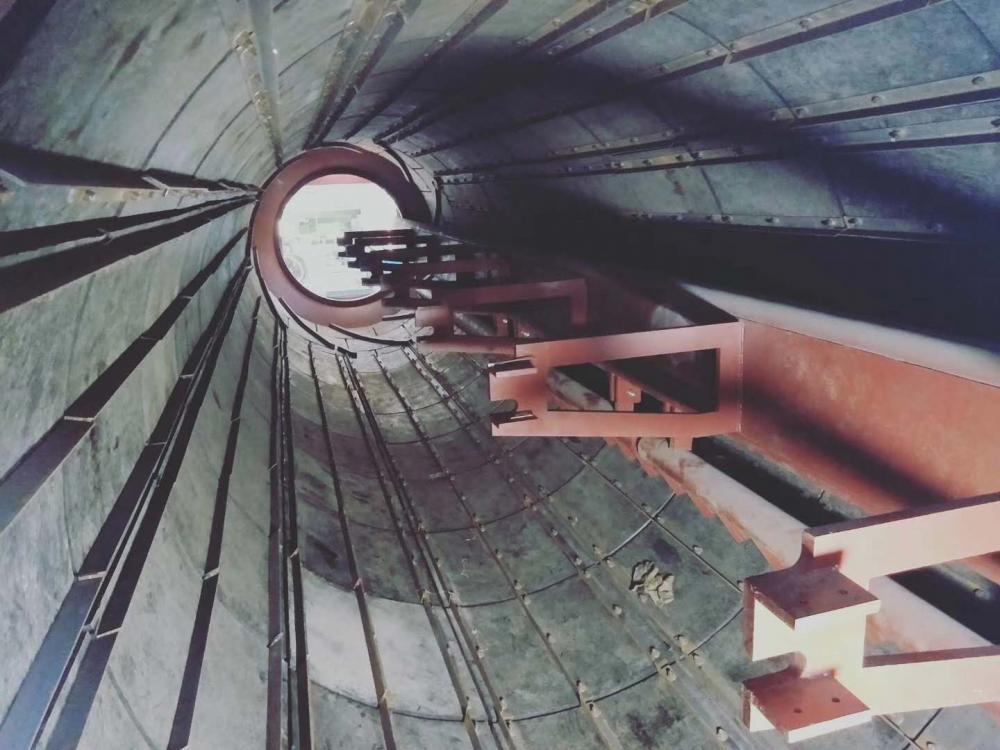

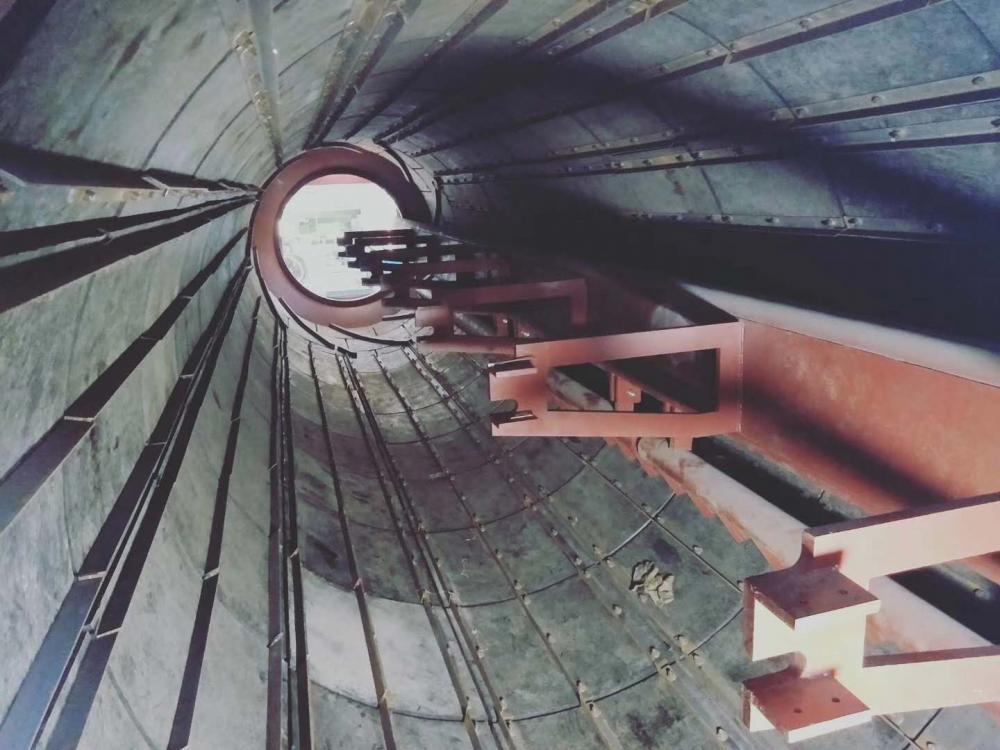

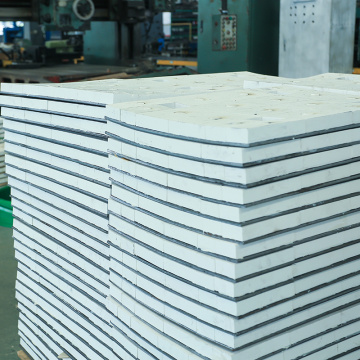

Rubber Lining Plate is used to protect the cylinder from the direct impact and friction of grinding materials and steel balls. Meanwhile, different shapes of lifting bars are also used to adjust the motion state of the mixture and grinding body, so as to enhance the grinding body's crushing effect on materials. It is helpful to improve the grinding efficiency, increase the output and reduce the metal consumption.Uhmw Pe It is short for the rubber lining board of the two ends and cylinder used by the ball mill, also known as the rubber lining and rubber lining. Rubber lining board adopts special formula,PE Engineering Plastics after high pressure vulcanization treatment, wear resistance is greatly improved service life is 1.5-2 times of the fierce steel lining board,Ptfe Engineering Plastics rubber's unique elastic buffer greatly reduces the fierce impact force. The whole set of machine rubber lining board is composed of cylinder lining board, cylinder lifting strip (also known as lamination) and other parts.

Features: 1. Low energy consumption 2, high wear resistance, impact resistance 3. Low noise 4, easy to install 5, corrosion resistance Performance Parameters: Rubber parameters of wet mill Project unit Index Tensile strength MPa > 22 Elongation at break % > 500 Permanent deformation % ≤25 Hardness of Sauer A 65±5 Wear reduction Cm³/1.61km ≤0.18 Operating temperature < 120 ℃ Mixer, ball - making rubber parameters Project unit Index Tensile strength MPa > 16 Elongation at break % > 300 Cracking strength MPa > 4 Hardness of Sauer A 60±5 Wear reduction Cm³/1.61km ≤0.2 Operating temperature < 100 ℃  Application: in the steel industry of cylinder mixer, granulating machine, ring cooling machine, embellishment mill, ball mill, desulfurization mill and other equipment. The common applications of rubber wear-resistant plate are: • Chute liner • Concrete mixer • Drum type peeling machine • Feeder liner • Hopper liner • Cylinder pelletizing machine • silo liner • Roll bushing board • Tank liner • Truck bucket liner • Feed cylinder liner • Scrubbing machine • Prone to wear and noise from any other application Optimal design Our rubber wear-resistant panels are designed to maximize performance and minimize maintenance downtime. We can customize the liner according to your operating data and production objectives. In addition, selected designs can be evaluated in advance by simulating liner performance. High reliability Rubber wear-resistant plates are manufactured by the company, and strict quality control procedures are implemented in each stage of research, development, design and production. This makes the whole supply chain can ensure stable, uniform high quality. Precise dimensions and precision tolerances ensure that rubber wear-resistant plates meet your needs. Combination of materials, better performance We offer a variety of different types of wear plates, spare parts and services. In some applications, the best performance can be achieved through a combination of different materials.

Application: in the steel industry of cylinder mixer, granulating machine, ring cooling machine, embellishment mill, ball mill, desulfurization mill and other equipment. The common applications of rubber wear-resistant plate are: • Chute liner • Concrete mixer • Drum type peeling machine • Feeder liner • Hopper liner • Cylinder pelletizing machine • silo liner • Roll bushing board • Tank liner • Truck bucket liner • Feed cylinder liner • Scrubbing machine • Prone to wear and noise from any other application Optimal design Our rubber wear-resistant panels are designed to maximize performance and minimize maintenance downtime. We can customize the liner according to your operating data and production objectives. In addition, selected designs can be evaluated in advance by simulating liner performance. High reliability Rubber wear-resistant plates are manufactured by the company, and strict quality control procedures are implemented in each stage of research, development, design and production. This makes the whole supply chain can ensure stable, uniform high quality. Precise dimensions and precision tolerances ensure that rubber wear-resistant plates meet your needs. Combination of materials, better performance We offer a variety of different types of wear plates, spare parts and services. In some applications, the best performance can be achieved through a combination of different materials. Rubber, metal, ceramic and polyurethane each have their advantages, and each material is used where it can best exert its properties. If desired, wear-resistant plates can also be manufactured from composite materials to be fully suited to the desired application.