Product Introduction:

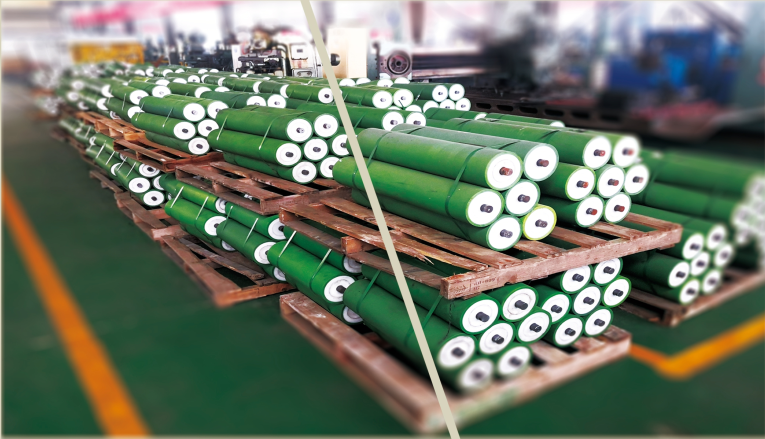

Ultra high molecular polyethylene nylon roller is a new product developed by our company in recent years. It has many obvious advantages over the traditional steel,PE Engineering Plastics ceramic and rubber roller in performance. It retains all the excellent properties of UHMWPE nylon,Ptfe Engineering Plastics with self-lubrication, impact resistance, noise and vibration elimination, anti-bonding, anti-corrosion, anti-aging and so on. Compared with traditional metal rollers, the popularization and use of ultra high molecular polyethylene nylon roller has very significant economic benefits in improving transportation capacity, protecting belts, reducing maintenance, saving energy and reducing consumption.Nylon Bush

Performance Introduction:

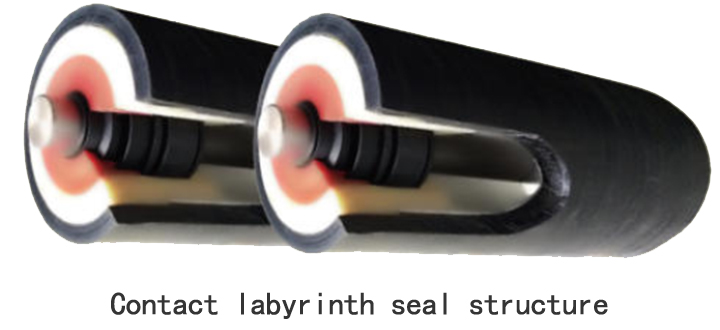

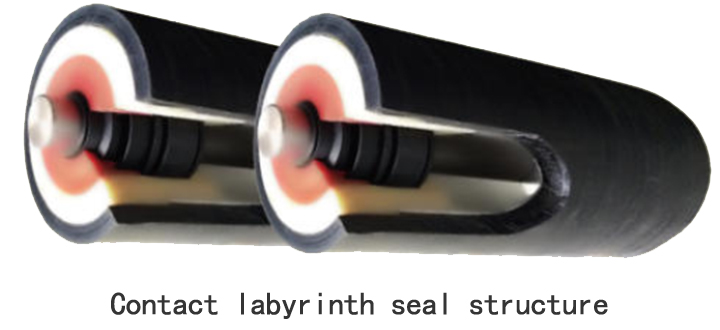

1. Sealing performance

Roller adopts contact labyrinth seal

", combined with contact

Type seal superior performance and labyrinth seal rotary resistance

The advantages of small force, dustproof, waterproof, grease is not permeable, long-term maintain its physical

Stable performance and speed, no bearing stuck phenomenon, reduced

The running resistance of the feeder.

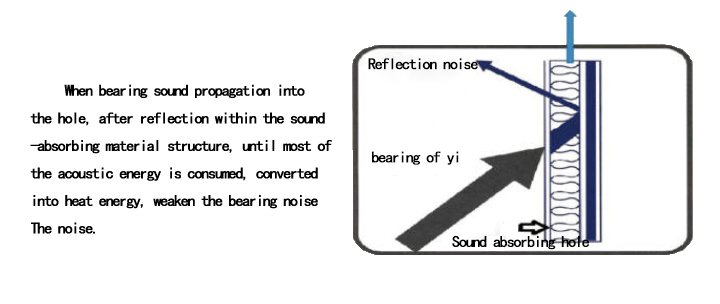

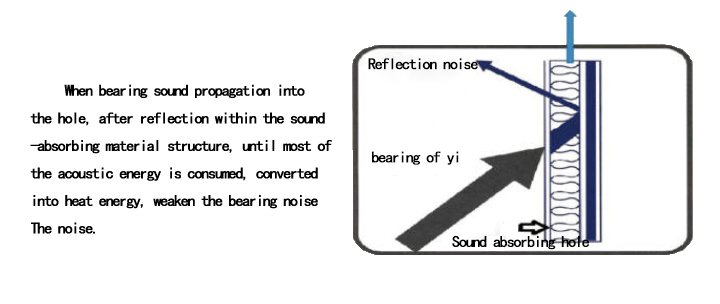

2. Silencing performance

The outer part of the bearing is equipped with a porous bearing sleeve to meet the required deflection requirements. Instead of a large-clearance bearing, the porous bearing sleeve plays a role of shock absorption and noise reduction, which will not affect the dialogue of downhole personnel under normal operation. Ultra high molecular weight polyethylene nylon has impact absorption and damping, can effectively eliminate noise and vibration, so as to protect the bearing from impact damage and greatly extend the overall service life of the roller. The noise produced by the steel roller is significantly reduced, greatly improving the working environment of underground workers.

The new idlers use new noise reduction technology,

3. Self-lubricating and non-bonding

The roller has non-adhesive surface, no rust, self-lubricating, so it has better protection for the belt, on the other hand, it will not produce the phenomenon of "bite" belt, even when the roller does not rotate, it will not damage the belt.

4. Corrosion and wear resistance

Ultra high molecular polyethylene nylon roller is a kind of saturated molecular group structure, so its chemical stability is very high, this product

6

Product can resist the erosion of strong chemical substances, in addition to some strong acid at high temperature has a slight corrosion, in other lye, acid is not corroded, can be applied in the concentration of less than 85% concentrated hydrochloric acid, less than 80% sulfuric acid, concentration of less than 20% nitric acid performance is quite stable, Therefore, the corrosion problem of rollers can be completely ignored in the operation of complex underground coal mine. Rollers have high corrosion resistance and wear resistance. Compared with steel rollers, the service life of rollers is longer than that of metal rollers. The wear resistance of roller rod skin is 7 times that of steel and 3 times that of nylon, and it is impact resistant and not easy to damage, which greatly extends the life of the belt.

5. Light weight

Ultra high molecular polyethylene nylon roller light weight, easy to install, greatly reduce the labor intensity of workers, save maintenance costs. Application: Roller used in coal, electric power, metallurgy, building materials, chemical industry, port and other conveyor belt equipment.

Performance Parameters:

Order no.

project

Single bit

And the number

1

Radial circular runout

mm

1 or less

2

Resistance of rotation

N

4 or less

3

Radial channeling

mm

1.2 or less

4

Axial load

Apply 15kN bearing load to the idler

The supporting roller is not separated from the supporting roller tube body

5

Performance of combustion

There is a flame burning mean s

3 or less

Flameless combustion mean s

10 or less

6

Water immersion seal

g

150 or less

Specification selection:

Order no.

The diameter of

The length of the

And the number

1

Φ 89 mm

300mm-1200mm

2

Φ 108 mm

300mm-1200mm

3

Φ 133 mm

300mm-1200mm

4

Φ 159 mm

300mm-1200mm

Application Field:

Roller used in coal, electric power, metallurgy, building materials, chemical industry, port and other conveyor belt equipment.