MC oil-bearing nylon series

Product Overview:

MC nylon is a new type of engineering plastic, with small mass, high strength, self-lubrication, wear resistance, corrosion resistance, insulation, shock absorption and noise attenuation, oil resistance, a wide range of use and other unique properties, its mechanical properties, heat resistance is significantly better than the general nylon products and the forming process is simple, can replace copper,PE Engineering Plastics major and other non-ferrous metals and alloys, plastic instead of steel, It plays an important role in the construction of national economy.Ptfe Engineering Plastics

MC nylon molding product size is not limited, product performance uniform, non-directional, can be made of large parts, can be made into pulley, slider, gear, water pump impeller, bearing, bearing, cage, high pressure sealing ring, gasket, electrical joints, can be widely used in machinery, textile, petrochemical, national defense and many other fields.Uhmw Pe

In recent years, with the in-depth research and attention to the characteristics of MC nylon at home and abroad, MC nylon in the medical field has also played its unique advantages because of its excellent comprehensive performance, so that it has a rapid rise in the status of reengineering plastics, become an important material, the use of increasingly expanded. MC nylon in mechanical aspects as vibration damping wear-resisting material instead of non-ferrous metal and alloy steel, a 400 kg nylon products, its actual volume is equivalent to 2.7 tons of steel or 3 tons of bronze, using MC nylon parts, not only improve the mechanical efficiency, reduce maintenance, and the general service life can be increased by 4-5 times.

Engineering plastics is our main business. Engineering plastics have many advantages and can effectively replace metal or ceramic materials in many cases. Moreover, when it comes to unusual technological applications, components made of engineering plastics are often the only option, making engineering plastics a true leader in innovation across key areas of the industry.

Hebei Tongye Metallurgical Technology Co., Ltd. produces a wide range of engineering plastics and thermoplastics that have better mechanical and/or thermal properties than more widely used general-purpose plastics such as polystyrene, polyvinyl chloride and polyethylene.

Compared with PE, PP, PVC and other general plastics widely used in packaging, engineering plastics can be selected when the mechanical strength or heat resistance requirements are higher, and it is simpler and more economical than high temperature plastics.

Through material mixing and modification, material properties can be optimized in a wide range to suit different applications. Therefore, engineering plastics have a variety of different properties.

The long-term service temperature of engineering plastics is between 100°C and 150°C. Often, such products are also referred to as technical thermoplastics.

Features:

Step 1: White

2. High strength, can bear the load for a long time

3. Good resilience and outstanding toughness

4. Compared with metal, low hardness, no damage to the grinding parts

5. High chemical stability

Performance Parameters:

Sn Indicates the item unit parameter

1. Tensile strength MPa 70

Elongation at break % 40

3. Elastic modulus GPa 1.85

4 Bending strength MPa 78

5 Compressive strength MPa 106

Brinell hardness HB 82

7 Specific gravity t/m3 1.2

8 Melting point 220 ℃

Water absorption rate % 0.2

10 Friction coefficient / 0.12

11 Impact strength kJ/m2 6.2

12 Continuous heat resistant temperature 170 ℃

13 Linear expansion coefficient K-1 5.5×10-5

Specification selection:

Project diameter (mm) Length (mm)

Pipes 10-260 ≤2000

Application Field:

Widely used in metallurgy, sintering, mining, cement factories, steel mills, textile factories and other industries. Such as manufacturing mixing machine, silo lining board, etc., good wear resistance, non-stick material, small impact load, energy saving, protect silo body lining, improve mechanical body wear resistance, high temperature resistance, corrosion resistance, protect equipment system parts, reduce maintenance costs, extend the service life of equipment.

Application scope and effect

1, manufacturing mechanical bearing bush, bushing, suitable for heavy load low speed, light load medium speed use. For example: metallurgical rolling machine universal joint spherical lining, coal machine bearing, calender rotor bearing, support tile, self-lubrication can avoid oil pollution, less oil or no oil mining, service life increased more than 5 times.

2, the manufacture of rolling mill coupling pin, instead of snake spring coupling, Ottoman coupling, oil-free self-lubrication effect is good

3, manufacturing transmission equipment roller, bushing, pad. Such as light industry beer, beverage filling line, refrigerating plant assembly line, coal mine, power plant coking coal transport chute, blanking funnel lining board; Ore dressing box, separator lining board, engineering transport vehicle liner board, etc., impact resistance, good wear resistance, and no corrosion, no pollution, no stick material.

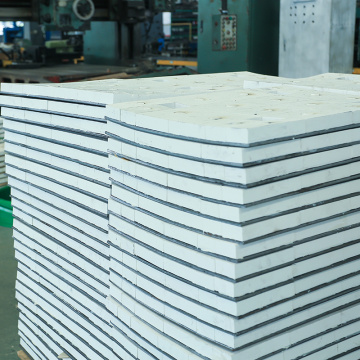

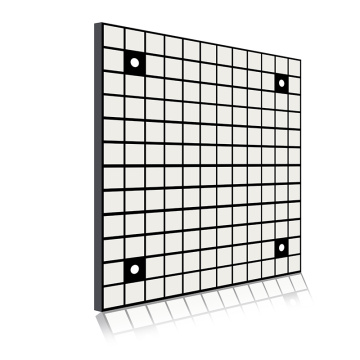

4, manufacturing metallurgical industry cylinder mixer lining board, silo, trough, chute, ball plate edge, plate bottom lining board, good wear resistance, non-stick material, impact load is small, energy saving. It can prolong the overall life of the equipment, protect the parts of the equipment system, reduce the maintenance cost, the mixing is uniform, the ball forming effect is good, and improve the operation rate of the mixer.

5, manufacture other mechanical parts, such as large worm gear, gear ring, press roller, piston ring, guide sleeve, filter plate

MC Nylon series products:

Mixing machine MC nylon lining plate making ball plate MC nylon lining plate