The cast wear-resisting steel and anti-wear steel are mainly austenitic manganese steel. Under certain conditions, the low-alloy steel with appropriate heat treatment also has a good effect. The graphite steel is used for lubrication and friction working conditions.PE Engineering Plastics

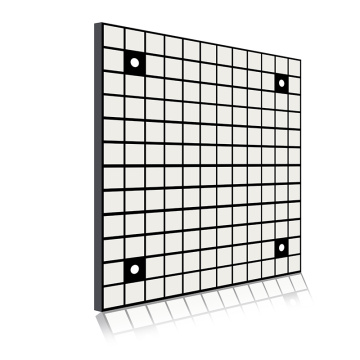

Wear-resistant high manganese steel is especially suitable for impact abrasive wear and high stress grinding abrasive wear conditions, often used in the manufacture of ball mill lining plate, hammer crusher hammer head, jaw crusher jaw plate, cone crusher rolling mortar wall, broken wall, excavator bucket teeth, bucket wall, railway turnout, tractor and tank track plate and other impact and wear resistant castings. High manganese steel is also used in: bulletproof steel plate, safe plate and so on.Silo Wearing Liners

High manganese steel is a typical wear resistant steel with austenite and carbide as cast structure. After water quenching treatment at about 1000°C, the tissue is transformed into a single austenite or austenite with a small amount of carbide, but the toughness is improved, so it is called water toughening treatment.

The most important characteristic of high manganese steel is that work hardening occurs rapidly on the surface under strong impact and extrusion conditions, so that the heart still maintains good toughness and plasticity of austenite while the hardened layer has good wear resistance. This is not comparable to other materials. But the wear resistance of high manganese steel shows its superiority only under the condition that it has enough to form work hardening, and it is very poor under other conditions. The typical Mn17 wet-resistant high-manganese steel increases the amount of manganese on the basis of Mn13 steel, improves the stability of austenite, prevents the precipitation of carbide, and then improves the strength and plasticity of steel, as well as the work-hardening ability and wear resistance of steel. For example, the service life of ZGMn18 railway fork used in the north is 20%~25% higher than that of ZGMn13.Nylon Bush

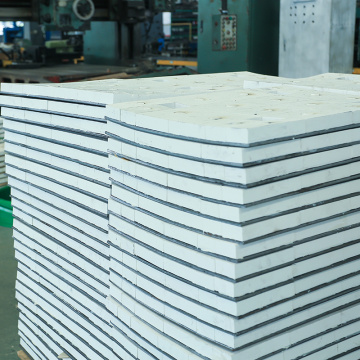

High manganese steel castings mainly adopt sand molding technology. Sand casting is widely promoted because of its mature technology and high production efficiency. There are also special casting. Special casting refers to the casting method which is significantly different from sand casting in terms of casting material, forming method, liquid metal filling form and solidification condition of metal in mold.

Manganese steel is widely used in almost every aspect of human production and life. About 90% of the world's annual production of manganese is used in the iron and steel industry, and 10% is used in nonferrous metallurgy, chemical industry, electronics, batteries, agriculture and other sectors.