Calendered microcrystalline cast stone liner Cast stone lining board is a kind of processed silicate crystalline material, using natural rocks (basalt, gabase and other basic rocks, as well as shale) or industrial waste slag (blast furnace slag, steel slag, copper slag, chromium slag, ferroalloy slag, etc.) as the main raw material, by battering, melting, pouring, heat treatment and other processes made of crystal arrangement is regular, hard, delicate non-metallic industrial materials. The cast stone has abundant resources, simple production process, low cost and excellent wear resistance, corrosion resistance and other properties.

The forming process of cast stone is divided into three categories: dissolution casting, sintering forming and hot direct sintering casting. At present, cast stone products have been widely used in building materials, chemical industry, metallurgy, mining and other industrial sectors. In many parts of the equipment cast stone is steel, iron, lead, rubber, wood and other ideal replacement materials, with the general metal can not reach high wear resistance, acid and alkali corrosion resistance, and has the advantages of extending the use of equipment cycle, reduce maintenance hours, improve production efficiency, reduce product costs and so on. Cast stone has been used in anti-corrosion engineering for decades. The cast stone has the characteristics of tight structure, small water absorption, high compressive strength and good wear resistance. In addition to the hot phosphoric acid, hydrofluoric acid and soluble alkali above 30℃, almost all inorganic acids, organic acids, alkali, salt, water and organic solvents have good corrosion resistance, cast stone is a brittle material, with high hardness, casting stone disadvantage is brittleness, not easy to withstand the impact of heavy objects.

PE Engineering Plastics

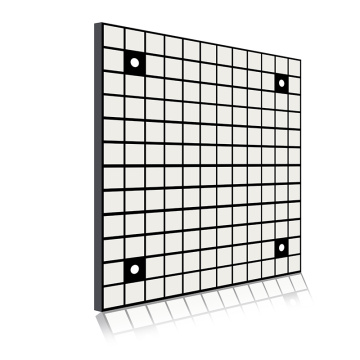

Features: 1. High hardness 2. Good wear resistance 3. Strong corrosion resistance, in addition to hydrofluoric acid and hot phosphoric acid, can resist any acid and base corrosion Performance Parameters: Project technical index Impact toughness ≥2.9KJ/㎡ Bending strength ≥82MPa Compression strength ≥860MPa Wear ≤0.082g/㎡ Acid resistance Alkali resistance sulfuric acid (density 1.84g/cm³) ≥99.5% Sulfuric acid solution (20%) ≥98.9% Sodium hydroxide solution (20%) ≥98.3% Application Field: Cast stone products mainly include cast stone Pipes, cast stone composite pipes, cast stone slabs and cast stone materials, which have been widely used in the serious wear and corrosion parts of electric power, coal, mining, metallurgy, chemical industry, construction and other industrial sectors, such as the bottom lining of scraper conveyor, chute lining, lining of wind machine shell, grinding machine inlet and outlet device and other parts. It is mainly used for anti-grinding of coal and electric power: cyclone, coal box, coal storage bunker, flow trough, coal drop bucket, ash bucket and anti-corrosion acid and alkali pool, floor and other parts of chemical and metallurgical industry. It is mainly available in black and white. Can extend the service life of parts or equipment for other materials more than ten times or even dozens of times. Because the toughness of the cast stone products is poor, the hardness is high, it is difficult to cut, and the products are generally processed according to a certain shape and size. The fixing method is masonry and Mosaic. Calendered microcrystal sheets are used for: ① Coal industry (gangue warehouse, medium barrel, scraper, bucket lifting machine, chute, sieve funnel and other inner wall wear-resistant lining board). ② Power generation industry (coal discharging ditch, coal bucket, furnace front warehouse, dry coal grid, dump machine, slag dregs, water treatment), etc. ③ Iron and steel industry (blast furnace mixing silo, sintering silo, feeder, ball making machine), etc. (4) Used in the chemical industry (anti-corrosion ground, pump foundation). ⑤ Used in paper industry (vacuum absorbent panel, molding plate, scraper). ⑥ Used for cement plant silo wall, pipe, etc. Used for Mechanical Equipment lining.

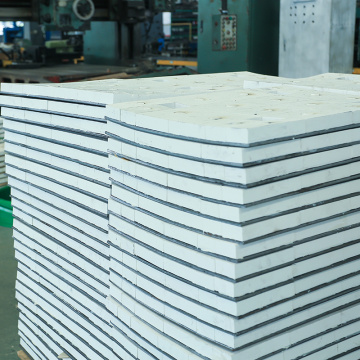

Cast-stone lining for silo and ballast ditch